Simulation brick pattern metal embossing production line

Simulation brick pattern metal embossing production line can help you do the embossing on metal, aluminum and other material like brick made the wall. The embossed metal sheet could be used on the wall Furnishings or building decoration. Here are some similar pictures for your reference:

There are more patterns I can not list all of them here, if you need to know, please contact us at any time.

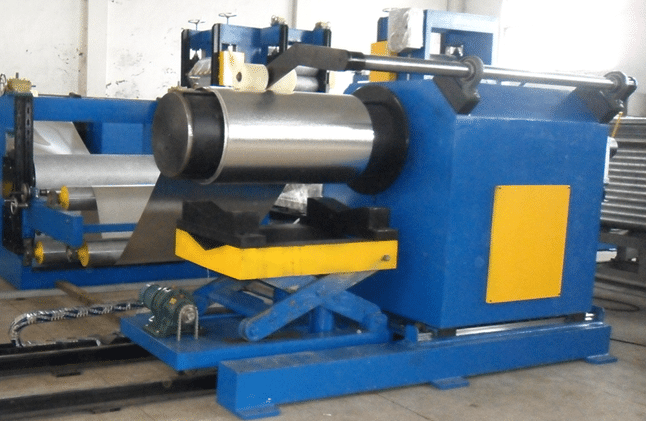

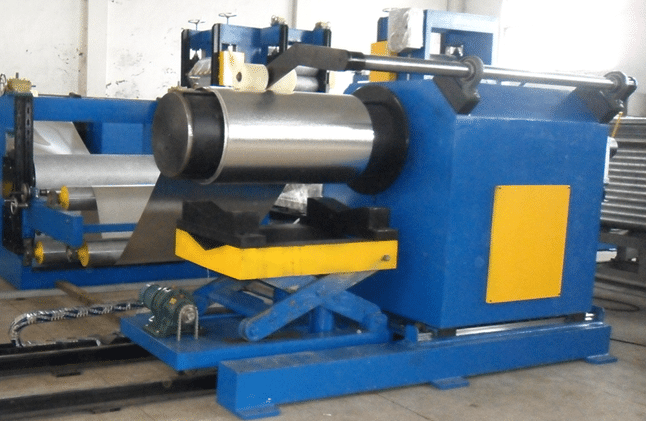

For the metal embossed machine to produce those embossed sheet, here are some main elements and parameters for your reference:

| 5T hydraulic Decoiler Max. Load Capacity: 5T Max. Coil width: 1000mm Coil Internal Diameter: 500mm 400NM magnetic with 1:6 reducer tension control the release wedge Segments To hydraulic Expansion spindle expansion :475-515mm With coil location manual control device Note: Here you also can choose the Manual Decoiler, price is be more lower but you have to load the coil yourself by forklift. And the machine working speed and efficiency will be quite lower too.

|

| |

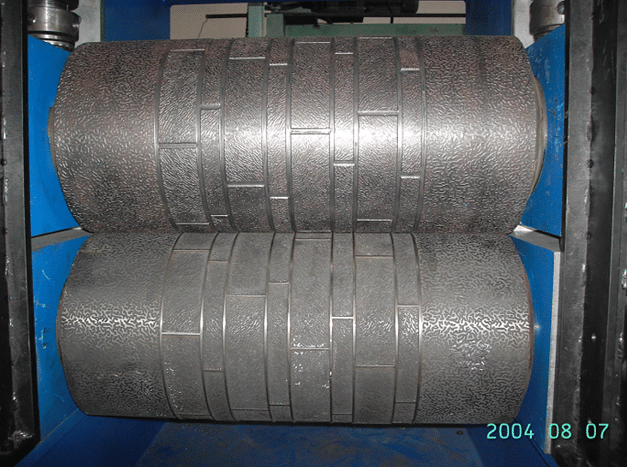

| (2) Embossing Machine (1 sets ) Embossing roller: ø440*1150 Material of embossing roller:60CrMnMo Pattern laser engraving as customer`s sample Hardness of embossing roller surface: HRC 58~62 Depth of hardness surface:5-10mm Bearing: Torrington spherical roller bearings ,TWB 3003136 Embossing thickness adjusted through the dial. Bearing box: 400*400*160mm Driving: 11kw AC motor,reducer:BWED53-17*11-11KW 4P Speed : 1-10m/min Pressure mode: hydraulic system, ø150 oil cylinder 2pcs Closed shields, safety devices. Emergency stop switch |

|  |

FAQ:

1.Does one Simulation brick pattern metal embossing production line can only produce one style product?

Not exactly. Our machines can produce more kinds of by change their rollers.

2. Do you have after sales support?

Yes, we are happy to give advice and we also send skilled technicians to your place to support the technical guidance. We will let your machines running that in order to keep your business running.

3. What can you do if the machine broken?

Our machine's warranty period is 12months. And if the broken parts can't be repaired, we will send the new one to replace the broken parts. And the only thing you need to do is paying the transport costs.

If beyond the warranty period, we can through the negotiation to solve the problems, and we will supply the technical support for the whole life of the machine.

Looking for ideal Simulation brick pattern metal embossing production line manufacturer & supplier ? We have a wide selection at great prices to help you get the target product. If you have any question, please contact us.

Looking for ideal Wall Brick Pattern Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Metal Embossing Production Line are quality guaranteed. We are China Origin Factory of High-quality Stainless Steel. If you have any question, please feel free to contact us.

Product Categories : Metal Processing Line

Mr. Cary xu

Mr. Cary xu