Metal Scaffold Plank Deck Rolling Forming Machine

Metal Scaffold Plank Deck Rolling Forming Machine is designed to make many sizes of scaffold plank decking panels in batch and fully autoamtic. The whole production line is controlled by PLC, through PLC you can conotrol metal scaffold plank decking working speed, production quantity and also the lengtah. Scaffold Metal Decks and Steel Planks are made in Galvanized and Painted with Plain Ends and Hook-on for Scaffolding System, Pipe and Fitting Scaffolding, the material thickness is from 0.8 to 1.5mm.

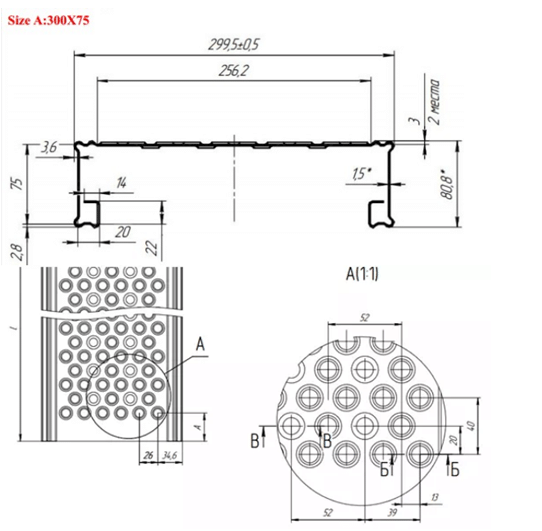

In the market, there are lots of metal decking types, take the following profiles for example:

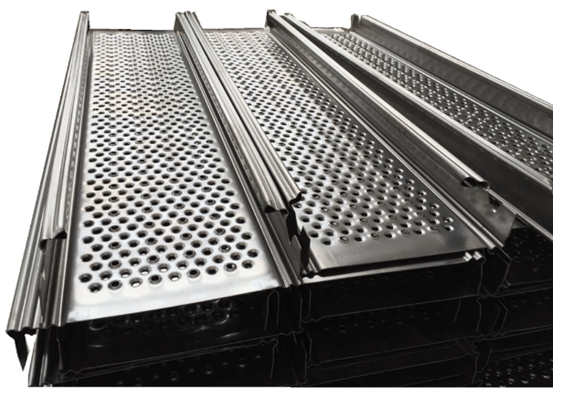

When using of the metal decking:

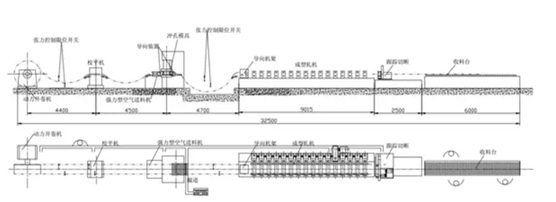

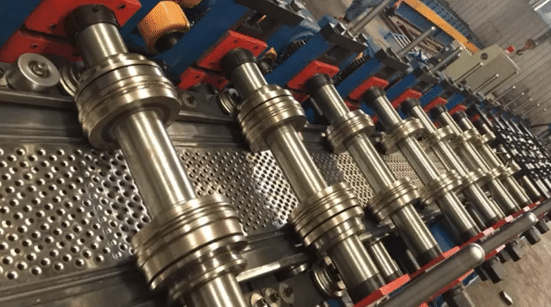

Metal Scaffold Plank Deck Rolling Forming Machine is designed like the following:

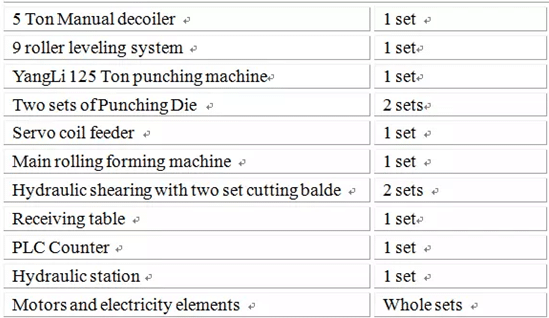

Metal Scaffold Plank Deck Rolling Forming Machine is composed by the fllowing elements:

Passsive decoiler, leveling machine, servo coil feeder, punching machinne, Roll Forming Machine, hydraulic System, shearing system, runout table, and PLC control system.

Machine working process:

Decoiler-->leveling-->servo coil feeding-->punching system-->roll forming machine-->sizing and shearing System--> runout table

Machine working area requirements:

Area needed: 35×3.0×5 meter long.

Machine working direction: from left to right

Machine electricity: 380, 50Hz,3 phrase or customize, please tell in advance

Hydraulic oil: 46# oil

Gear oil: 18 # hyperbolic gear oil

PLC CONTROL SYSTEM of metal decking system:

The PLC control system, touch screen interface. The operator through the procedures for setting the automatic operation (programmable control and process control monitoring and Implementation for the

operator to control production line and modify the control parameters, and real-time monitoring the running state of the equipment, operation parameters and fault indication etc.. Part length digital setting, the length of the workpiece can be adjusted. Real time monitoring equipment

Operation status and fault indication.Operation mode has two kinds of manual / automatic. With manual, automatic switching function: in manual mode, single operation, convenient maintenance; in the automatic mode, the entire production run, startup sequence; across the board with emergency stop button, easy to handle emergencies to ensure equipment and the safety of the operator.

More details pictures of the metal decking machine:

For this machine, if you need to know more information, please contact us at any time.

FAQ:

1.Does one Metal Scaffold Plank Deck Rolling Forming Machine can only produce one style product?

Not exactly. Our machines can produce more kinds of by change their rollers.

2. Do you have after sales support?

Yes, we are happy to give advice and we also send skilled technicians to your place to support the technical guidance. We will let your machines running that in order to keep your business running.

3. What can you do if the machine broken?

Our machine's warranty period is 12months. And if the broken parts can't be repaired, we will send the new one to replace the broken parts. And the only thing you need to do is paying the transport costs.

If beyond the warranty period, we can through the negotiation to solve the problems, and we will supply the technical support for the whole life of the machine.

Looking for ideal Metal Scaffold Plank Deck Rolling Forming Machine manufacturer & supplier ? We have a wide selection at great prices to help you get the target product. If you have any question, please contact us.

Looking for ideal Popular Scaffold Products Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Plank Deck Rolling Forming Machine are quality guaranteed. We are China Origin Factory of Metal Steel Line. If you have any question, please feel free to contact us.

Product Categories : Floor Deck Roll Forming Machine

Mr. Cary xu

Mr. Cary xu