Roofing metal steel sheet

roll forming mahcine

Description of products :

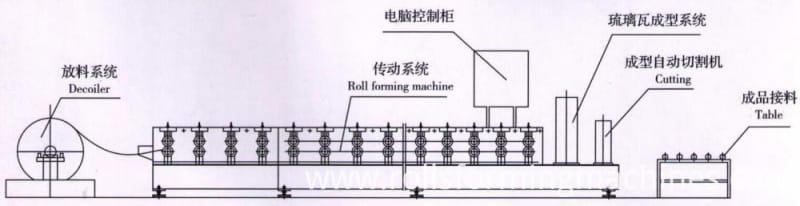

trapezoidal roof tile Roll Forming Machine production process

decoiling-guiding-roll forming-cutting-products

Production process:

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Step formed→ Auto cutting→Products receiving

details of trapezoidal tile roll forming machine

Production parameters

Processing material: colored steel plate, galvanized plate, or aluminum plate

Material thickness:0.3- 0.8mm

Material hardness:195 mpa---350 mpa

Material width:1250mm Wave length:194 mm

Formed width: 970 mm Step height: 30 mm

Step length:150mm---380mm(adjustable) Forming speed:4 m/min

| No. | Main parameter |

| 1 | Length of the main part | 7500*1650*1500mm |

| 2 | Weight of main part | 4.5T |

| 3 | Voltage | 380V/50HZ3Phase(as customer`s request) |

| 4 | Roller fixer | Midddle plate welded |

| 5 | Frame | 350 H steel welded |

| 6 | Frame thickness | 16mm |

| 7 | Drive mode | chain |

| 8 | Material of rollers | 45#steel, surface hard chromium plating |

| 9 | Material of shafts | 45#steel |

| 10 | Diameter of shafts | Φ80mm |

| 11 | Number of rollers | 13rollers |

| 12 | Main power | 5.5kw

|

Packing and shiping:

| Packaging Details: | 1. one 20ft container for loading one set machine with Manual Decoiler; 2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; 4. All Components Fixed by steel wire with Container. |

| Delivery Detail: | 45 days after receipt of buyer's deposit |

Service

a.If buyers visit our factory and check the machine, we will teach you how to install and use the machine,and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

c.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

2.After Sevice

3.a.One year guarantee for whole machine.

b.24 hours technical support by email or calling

c.If there is any problem found of the machine, we will repair it for free in one year.

Company information

factories and associated nterprises, concerning with the design, development and production of cold roll forming machines,material of building.

It is located in northwest of CangZhou, as a long history of cold roll forming machine production base. All products comply with international quality standards

and are greatly appreciated in variety of different markets throughout the world, such

as Asia, Africa, Europe,South America, and Australia and so on.

Looking for ideal Trapezoid Steel Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Trapezoid Steel Roof Forming Machine are quality guaranteed. We are China Origin Factory of Roofing Sheet Machines. If you have any question, please feel free to contact us.

Product Categories : Roofing Sheet Roll Forming Machine > Glazed Tile and Ridge Cap Roll Forming

Mr. Cary xu

Mr. Cary xu