Automated Portable Half ‑Round Rain Gutter Forming Machine

The ZTRFM‑brand Automated Portable Half‑Round Rain Gutter Forming Machine is engineered for on‑demand production of half‑round gutters and downspouts from color‑coated steel coil. Certified by CE and SGS, this model ZTAC unit offers both manual and optional automatic decoilers, and features a modular design that supports rapid profile changeovers and consistent dimensional accuracy.

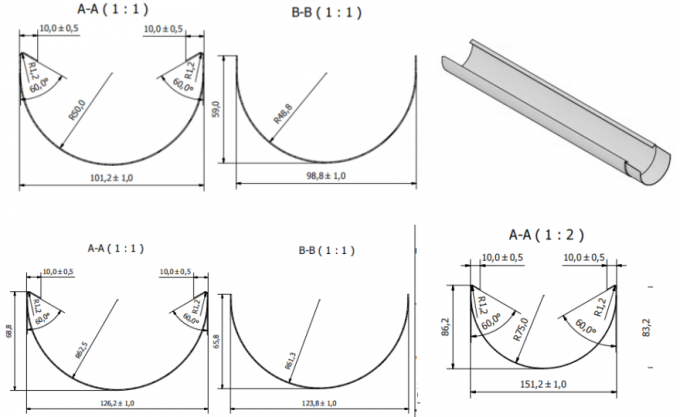

The Drawing Profile:

Half Round Downspout Rolling Forming Equipment of Key Features

• Dual Decoiler Options: Choose a simple manual stand or upgrade to an automatic uncoiler—both handle coils up to 3 tons, ensuring smooth material feeding and minimal setup time.• Versatile Profile Capability: Produces European‑bead, double‑bead, or reverse‑bead half‑round gutters (up to 19.5 ft continuous lengths) by swapping minimal tooling.

• Precision Forming & Cutting: Thirty‑pass roll stations with H350 steel base frame deliver straightness within 1 mm/m. A hydraulic “stop‑cut” shear offers repeatable cuts from 100 mm to 6 000 mm, with length tolerances of –0/+1 mm.

• Robust Drive & Control: Main drive powered by a 7.5 kW motor; hydraulic pump (4 kW, air‑cooled) maintains oil temperature in long runs. Siemens PLC, Siemens touch screen, and Yaskawa inverter ensure intuitive operation in English or Chinese.

• Safety & Ergonomics: Fully enclosed transmission housing, safety chains and gears, plus a cantilever‑style control cabinet for operator comfort.

Half Round Gutter Forming Equipment of Technical Specifications

| Specification | Details |

| Material Thickness | 0.3–0.7 mm |

| Forming Speed | 0–25 m/min (adjustable) |

| Cutting Length | 100–6,000 mm (–0/+1 mm tolerance) |

| Main Motor | 7.5 kW gear-reducer type |

| Hydraulic Motor | 4 kW, air-cooled |

| Roll Stations | 18–20 passes |

| Frame | Bolted H-beam 350 mm with 200 mm legs |

| Chain Drive | Single-row 1″ chain |

| Control System | Siemens PLC & touch screen; Yaskawa inverter |

| Decoiler | Manual or automatic (3-ton capacity) |

| Power Supply | 380 V / 50 Hz / 3-phase |

| Delivery Time | ≈ 45 working days |

| Monthly Capacity | 30 sets |

| Certification | CE, SGS |

Half Round Rain Gutter Roll Forming Machine Workflow

1. Decoiling: Unwind the coil smoothly via manual or powered decoiler.2. Guiding & Punching: Precision guides align material; optional in‑line punch for mounting holes.

3. Roll Forming: Material passes through sequential roll stations, gradually shaping the half‑round profile.

4. Cutting: Servo‑controlled hydraulic shear performs fixed‑length cuts without stopping the line.

5. Discharge & Stacking: Finished sections exit onto an adjustable run‑out table or stacking rack.

This streamlined workflow minimizes material handling and ensures high throughput at speeds up to 25 m/min.

Heavy‑Duty Energy‑Efficient Half‑Round Downspout Production Machine: Advantages

• Rapid Profile Change‑Over: Tool sets can be swapped in under 30 minutes, reducing downtime between jobs.• Exceptional Accuracy: Advanced PLC controls maintain strict tolerances for industry‑leading uniformity.

• Durable Construction: Heavy‑duty frame and hardened rollers resist wear, extending service life and reducing maintenance.

Residential & Commercial Half‑Round Rain Gutter Rolling Equipment Applications & Markets

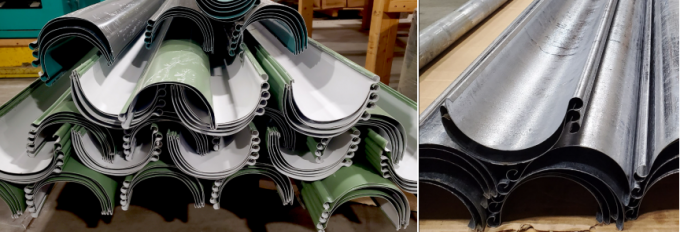

Ideal for roofing contractors, metal fabricators, and on‑site production teams, this machine serves both residential and commercial projects—manufacturing gutters, downspouts, and decorative profiles in materials such as galvanized steel, aluminum, copper, and zinc. Its portability and rapid setup make it perfect for remote job sites and custom installations.

اللغة العربية

اللغة العربية